- PRODUCTS

- INDUSTRIES

- RESOURCES

- SUPPORT

How To Get Accurate Flow Measurements Despite Flow Disturbers

Flow meter accuracy is critical for process control but can be hampered by upstream and downstream flow disturbers. This problem may be addressed during the design process, though in some circumstances it’s impossible to eliminate disturbers.

What Are Flow Disturbers?

Anything that impedes flow upstream or downstream of a flow meter is a flow disturber. This includes piping configurations, like elbows, tees, or reducers. Valves also create flow disturbances, including butterfly, check, or control valves. Nearby pumps discharging into a pipe near the meter would disrupt the flow profile. Items protruding into the pipe, such as probes, can be problematic as well.

Flow Disturbers’ Effects On Flow Measurement

Flow disturbers can create an asymmetric velocity profile or swirl, resulting in significant flow measurement errors. Flow meter inaccuracy can be from under-reading or over-reading. The amount and direction of inaccuracy depends on various factors. These include flow velocity and profile and type of metering technology.

Flow meter manufacturers typically specify the amount of upstream and downstream straight pipe required for installation. This may be 5 to 10 or even more pipe diameters of straight pipe before and after the meter. By following the recommended installation requirements, the flow is “conditioned” and accurate flow measurements are obtained.

Options If Flow Disturbers Cannot Be Avoided

Ideally, enough straight pipe runs are provided for accurate flow measurement during design and construction. But in the real world, it’s often impossible to ensure enough straight pipe before or after the meter. The facility site may be too compact, or the flow meter may be part of a retrofit project. Regulators may add a requirement for flow measurement after a facility is already online. And sometimes flow meter locations are determined after the system is already constructed.

In some cases, flow straighteners or conditioners can be installed to reduce the amount of straight pipe needed. Several types of these devices are available, in the form of perforated plates or tube bundles. However, these devices don’t work with all types of flow meters. Also, pressure losses may occur depending on the type and installation of the flow conditioner.

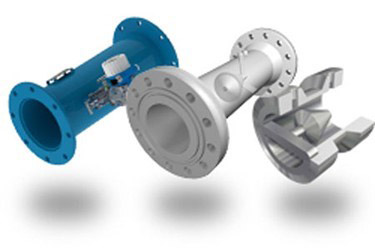

A better option may be to use a flow meter designed for circumstances where sufficient length of straight run pipe is not possible. For example, the V-Cone® flow meter from McCrometer is designed to flatten out the flow profile, providing a true flow measurement through the meter.

Built-In Flow Conditioning

A V-Cone flow meter is a differential pressure (DP) type of meter, with a cone mounted in the center of a tube. Two pressure transmitters, one upstream and one in the downstream face of the cone, measure the pressure difference. The pressure measurements are then used to calculate the flow rate.

The cone actually conditions the flow before measurement. V-Cones have a very small footprint and do not need the upstream and downstream flow conditioning to operate correctly.

However, they are not recommended for measuring flows with solids or particulates, to avoid clogging the pressure transmitter ports.

Advantages Of V-Cone Flow Meters

A great advantage is that the V-Cone can be mounted very close to a flow disturber, needing zero diameters of straight pipe. The flow meter can be installed between two double elbows and still maintain 0.5 percent accuracy of reading. It’s also the only meter that can be used in a downflow application.

For municipal water applications, a special version of the V-Cone is also available. The VM V-Cone® System Flow Meter is specifically set up for municipal applications. It’s a one-stop package that includes the device (spool piece with cone), a three-way manifold valve, and attached DP transmitter. A flow computer with remote display can also be provided and can interface with existing SCADA systems if desired.

In industrial applications, the meters can be provided with noncorrosive material, like Monel or stainless steel.

Tight Fits And Retrofits

Where room for straight pipe is plentiful, electromagnetic or ultrasonic meters are often used. But where real estate is lacking, such as booster stations or well sites, the V-Cone provides highly accurate measurement regardless of flow disturbers.

Retrofit projects are excellent applications for V-Cone meters. Existing infrastructure often contains flow disrupting components that would be expensive and difficult to relocate. With a V-Cone, the cost of additional piping is avoided and process disruption is minimized.

Air Flow Measurements

V-Cones also measure digester gas or compressed air within a small footprint. This saves the cost of extra stainless-steel pipe that would be needed for flow conditioning with thermal dispersion meters. And the V-Cone can be designed with only 5” of head loss for aeration applications.

Choosing The Right Flow Meter

Whether designing a new facility, retrofitting an old facility, or just adding a meter, review all the options. Installing the wrong flow meter can lead to inaccurate measurements and process control issues that can last for years. Flow meter manufacturers’ representatives are very knowledgeable and highly experienced. Engage them and use their expertise to find the best meter for your application.