- PRODUCTS

- INDUSTRIES

- RESOURCES

- SUPPORT

Flow Meters for Industrial Applications

Flow Meters for Industrial Applications

Industrial process facilities require exceptionally durable, highly precise flow measurement instrumentation. Power plants, including cogeneration, paper mills, chemical and petrochemical plants, metals and mining, food & beverage and more depend on the accurate and economical handling of air, water, steam, liquid, gas, or energy.

McCrometer flow meters offer unbeatable value in cost of installation and ownership, and serve a diverse market with flow measurement solutions to fit each customer’s application needs. Listening to customers and innovating unique solutions is our specialty.

What Our Customers Are Saying

"Steam injection plays a critical role in our poultry operations. The measurement accuracy of the V-Cone Flow Meter provides us with better overall control and process efficiency. It also requires less space to install, which gives us equipment layout flexibility."

Tony Nichols, Pilgrims Pride

Featured McCrometer Industrial Flow Meters

Electromagnetic Flow Meters

Electromagnetic flow meters, designed without moving parts, are highly favored in the industrial market due to their reliability and minimal maintenance requirements. Ideal for a range of applications, from food and beverage production to paper mills and power plants, mag meters offer precision and consistency even in challenging environments.

Their compact design fits tight spaces, and their operation is unaffected by debris, making them robust and dependable. Additionally, electromagnetic flow meters excel in remote locations where battery life and accuracy are crucial, ensuring seamless operation and optimal performance across various industrial processes.

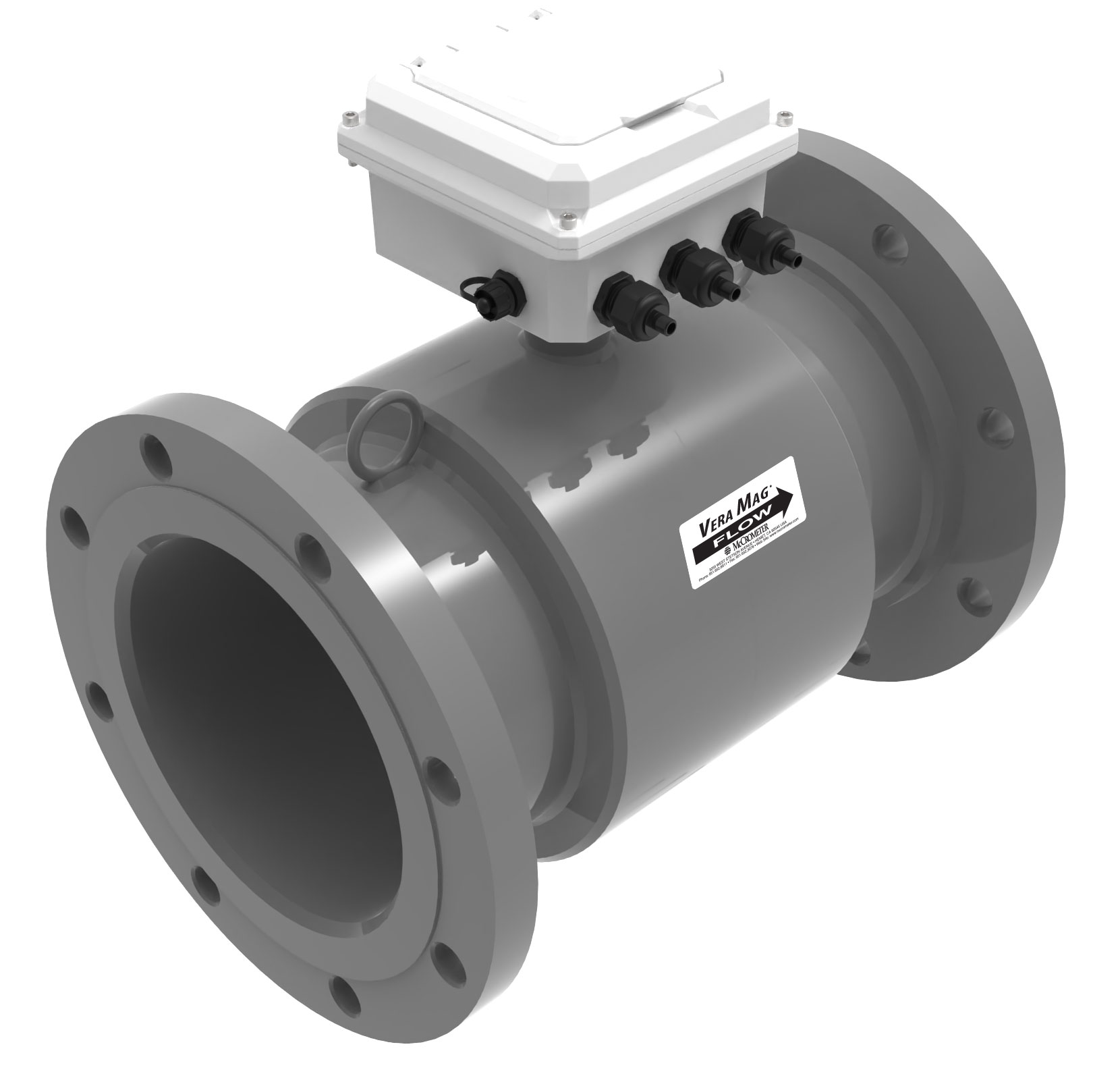

Vera Mag® 3000

The Vera Mag® 3000 mag meter delivers exceptional performance and critical measurement data with the ProComm GO for long lasting flow measurement in harsh conditions with little maintenance.

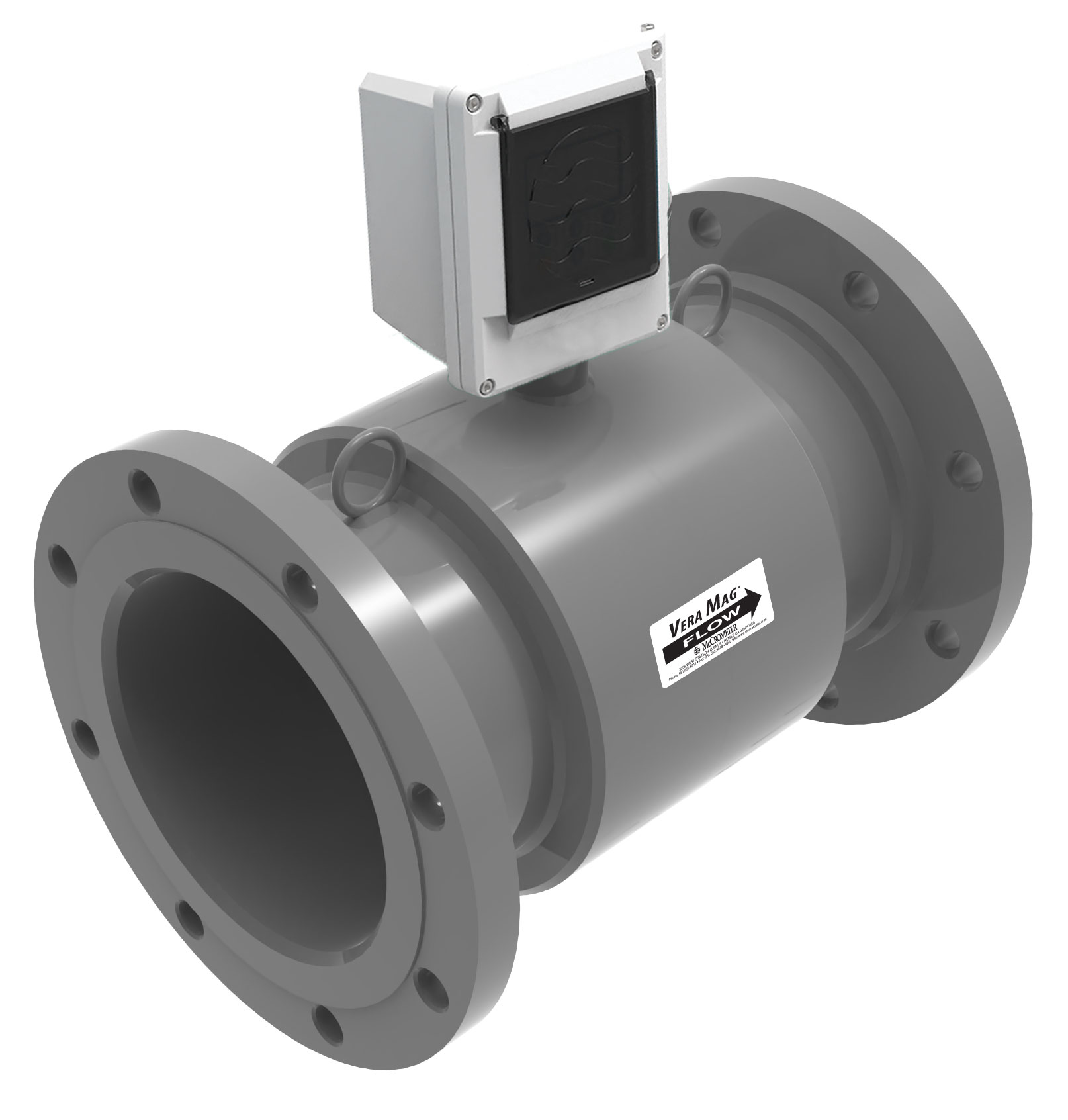

Vera Mag® 5000

Designed for challenging industrial water and wastewater applications, the Vera Mag® 5000 provides unmatched accuracy in measuring conductive liquids, slurries, and sludge flows with zero debris issues.

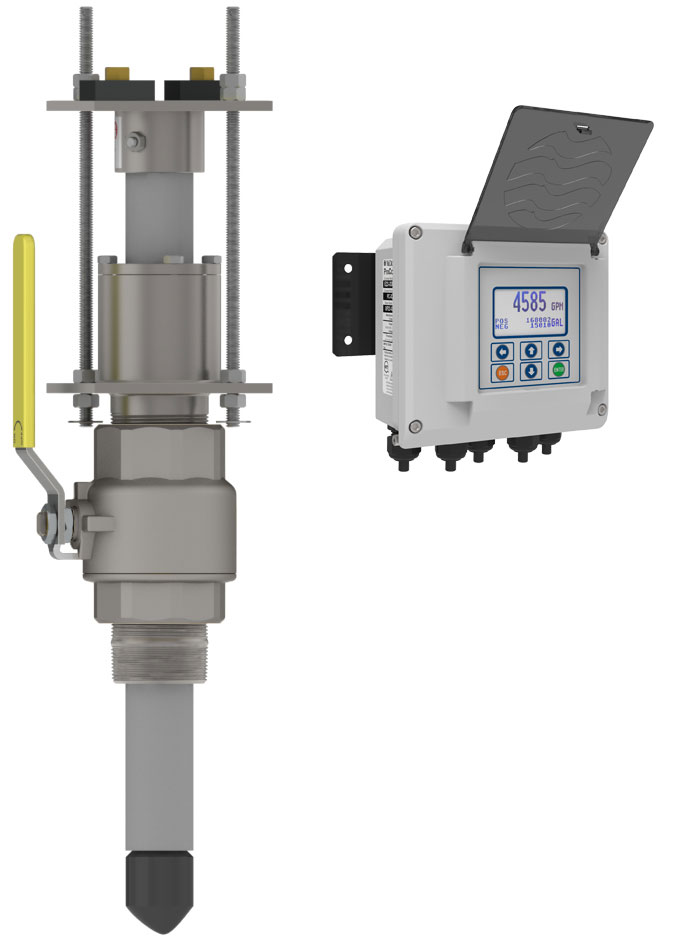

FPI Mag® Plus 3000

The FPI Mag Plus 3000 mag meter is ideal for sites that have never before been metered. Combining ease of installation, reliability, and cost savings, the FPI Mag Plus 3000 is rated for various flow media.

FPI Mag® Plus 5000

Equipped with the ProComm Max, the FPI Mag Plus 5000 enhances accuracy its multi-electrode design, delivering precision that rivals full-bore mag meters and makes flow monitoring simple and precise.

Field Mag® 3000

Field Mag 3000 is a rugged, battery-powered mag meter designed for water transfer, produced water, and mining operations, featuring durable epoxy liner and easy connections.

Field Mag® 5000

Field Mag 5000 is a robust, powered mag meter for water transfer and mining, offering high temperature and pressure ratings, reliable Modbus data, and easy installation.

SPI Mag® 3000

The SPI Mag 3000 Meter provides a highly cost-effective solution for the accurate measurement of liquid flow in closed conduit, pressurized pipe applications with the ProComm GO as a major highlight.

SPI Mag® 5000

Paired with the ProComm for enhanced data communication and integration, the SPI Mag 5000 uses velocity and pipe diameter information to measure flow accurately across a wide range.

Advanced Differential Flow Meters for Industrial

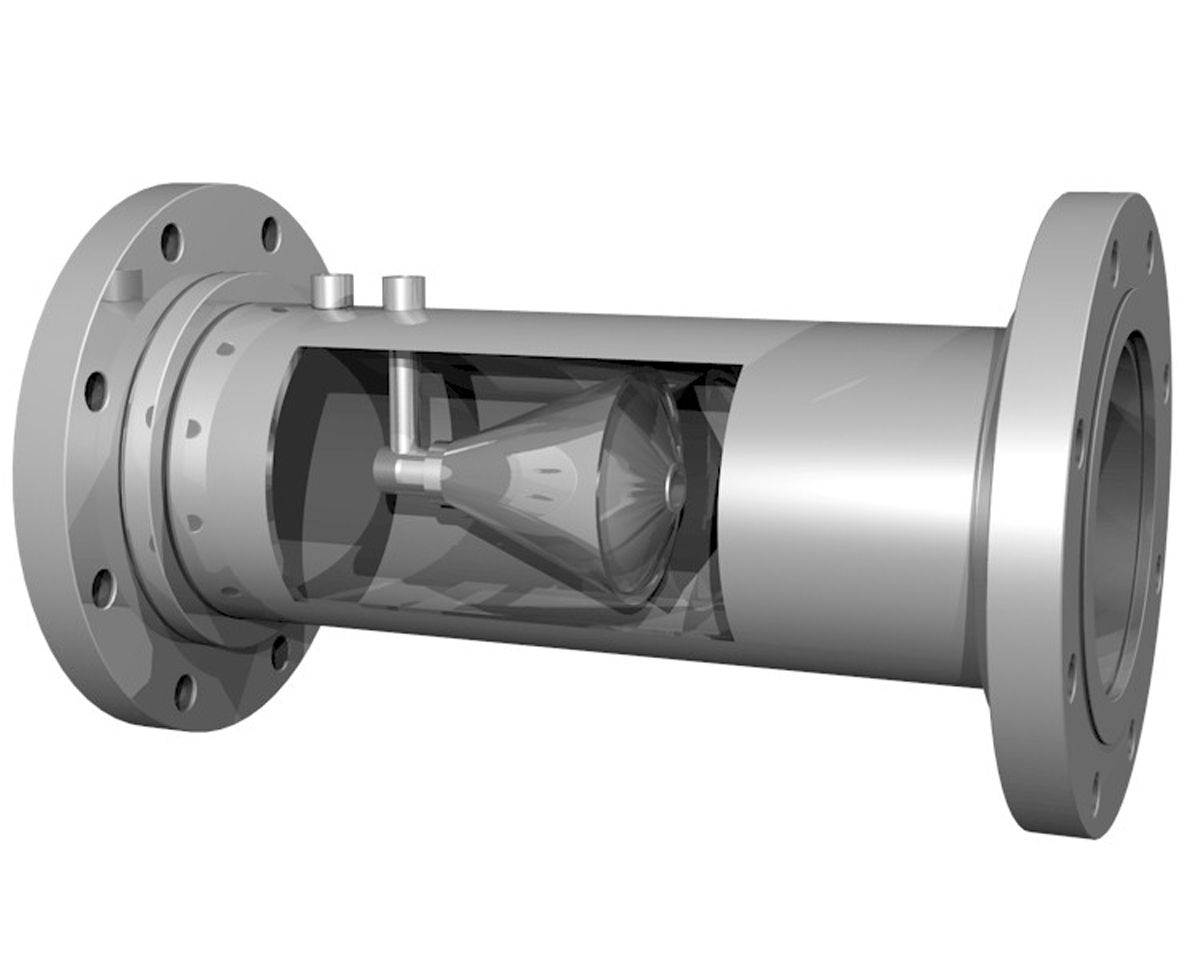

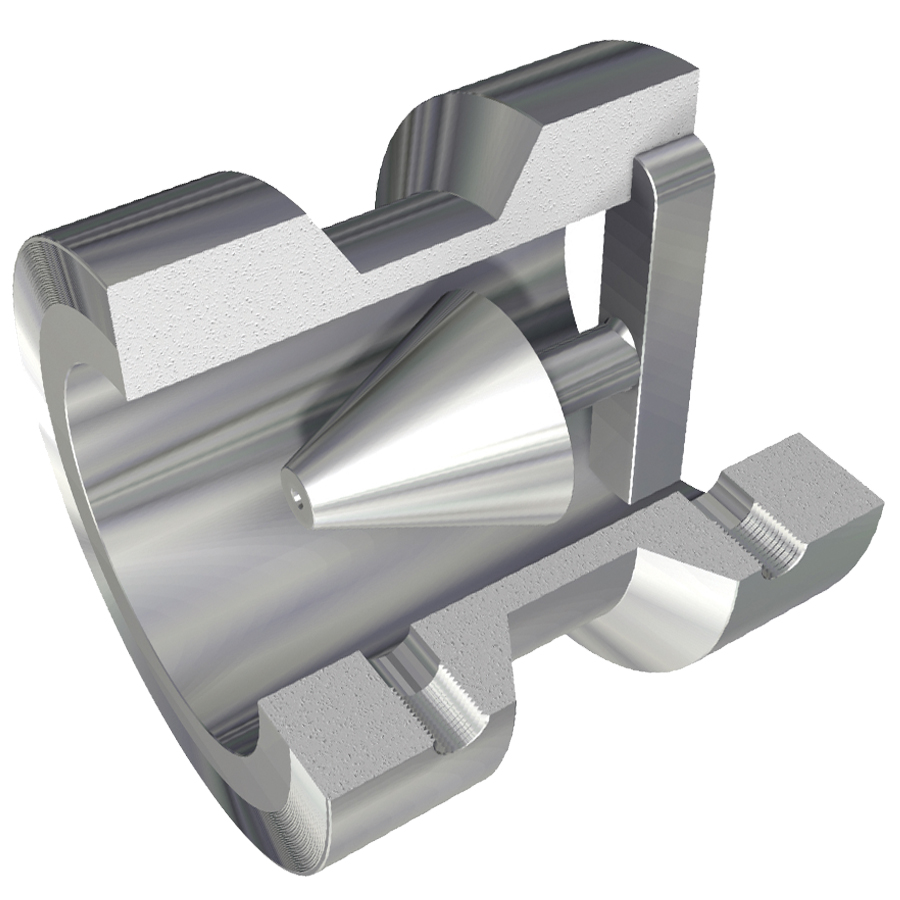

Engineers can rely on McCrometer’s versatile differential pressure V-Cone flow meter for accurate and repeatable measurements across various industries. Known for its 25+ year lifespan and superior performance since 1985, the V-Cone is a favorite for industrial and oil and gas projects. Its reliability and customization make it ideal for demanding installations, measuring fluids such as water, crude oil, wet gas, LNG, steam, and more.

V-Cone® Meter

Known for its superior accuracy and repeatability in both mild and harsh environments, the V-Cone® Flow Meter is an advanced differential pressure instrument designed for challenging conditions.

Wafer-Cone® Meter

The Wafer-Cone™ delivers accuracy and minimal maintenance with its compact, flangeless design, making it ideal for tight spaces and retrofits. It offers a cost-effective solution for various applications..

Propeller Meters for Industrial

McCrometer’s propeller flow meters deliver outstanding value with minimal installation and maintenance costs. Known for their user-friendly design, robust construction, and dependable performance, these meters set the industry standard for accuracy and durability.

McPropeller® Meter

The Mc®Propeller is the best-selling propeller meter in the United States. Engineers have trusted it since 1955 for its life-long components, affordability, ease of installation, and operability in the industry.

Meter Electronics and Telemetry Solutions for Industrial Applications

Flow Meter Electronics and Connected Hardware

McCrometer's connected telemetry solutions and electronics provide seamless,reliable remote meter reading for accurate,timely data collection, simplifying volumetric management while providing comprehensive flow measurement and data transmission. Battery-powered for remote locations, these accurate and user-configurable devices ensure minimal maintenance, with options for compatibilty and versatile input/output connections

ProComm® GO

The ProComm GO is a cost-efficient, battery-powered signal transmitter, ideal for remote locations without AC/DC power. User-configurable, with accurate flow rate and velocity display, and isolated pulse outputs.

ProComm® Max

The ProComm Max signal transmitter offers advanced features and enhanced accuracy with a multi-point curve-fitting algorithm, dual 4-20mA outputs, RS485 port, and backlit LCD.

FlowCom®

The battery-powered FlowCom remote telemetry unit provides wireless telemetry of flow and sensor data. Connects to AMI-compliant devices with pulse options and 5V analog outputs.

Open Channel Flow Solutions for Industrial Applications

Hach’s Flow Solutions by McCrometer

Acquired by McCrometer, the Hach Flow product line delivers open channel solutions to municipalities with integrated systems that ensure accurate flow measurement. Known for quality and operational reliability, Hach water management products are designed for open channel applications; visit our FAQs page to learn more about Hach Flow capabilities.

FLO-DAR® Sensor

The FLO-DAR sensor provides users with highly accurate non-contact flow measurement from above. Build with precision in mind, the sensor ensures flow data to be uninterrupted or disturbed.

FH950 Flow Logger

Designed for portable use in the field, the battery-powered and lightweight FH950 flow logger excels in measuring turbulent, noisy, or shallow flows in various municipal applications.

FL900 Flow Logger

Reliable and cost-effective, the FL900 flow logger is specifically designed to reinforce engineer safety and enhance efficiency in challenging open channel applications for municipals.

FL1500 Flow Logger

The FL1500 stationary flow logger offers agile, accurate, and integrated flow measurement through multi-sensor data collection operations, making it ideal for various water quality monitoring needs.

Data Delivery Service (DDS)

Our monthly subscription solution enables any field service team to accurately manage data collection for flow measurement. Services available using industry-level flow monitoring products and operation.

FSDATA™ Online Application

Unlock flow measurement data with FSDATA, a comprehensive digital software solution that allows you to remotely access, monitor, program, and report on all of your field instruments from wherever.

Depending on a pipeline’s flowing media and influences to process, the flow dynamics within a pipeline can vary widely. The ideal pipeline configuration for accurate measurement of flow is usually a straight pipe with consistent media conditions. However, many processes by their very nature tend to be unstable and create irregular flows within a pipeline.

Flow straighteners and conditioners may offer an answer to this problem, eliminating swirl and providing a stable velocity flow profile, but a major drawback is that they can increase head loss.

In this video, we explore the principles of a groundbreaking flow meter with built-in flow conditioning as a solution: the V-Cone flow meter.

How to Choose the Best Industrial Process Flow Meter:

Instrument, process, facility, and consulting engineers worldwide must confidently choose a meter that fits the specifications of their project or plant. Some projects require a greater need for needle-threading accuracy while others have a larger preference for scalable installations, with control over data transfer capabilities and improved data measurement qualities.

When deciding what type of industrial flow meter, consider the following factors to save on installation costs, improve measurement quality, and enhance flow measurement accuracy:

-

Application of Industrial Flow Meters

Industrial flow meters are utilized across diverse sectors, including water and wastewater treatment, oil and gas production, chemical processing, power generation, and HVAC systems. They play a crucial role in monitoring and controlling fluid flow to ensure process efficiency and regulatory compliance.

-

Signal Outputs Needed

Industrial flow meters typically offer various signal output options to align with existing control and monitoring systems. Common outputs include 4-20 mA, pulse, Modbus, HART, and Profibus, providing necessary data for process control and optimization.

-

Flow Range Compatibility

Ensure the meter can accurately measure the maximum and minimum flow rates of your application. Selecting a meter with a suitable flow range prevents underperformance or overloading, enhancing accuracy and longevity.

-

Signal Output Options

Choose a meter that offers the necessary signal outputs, such as 4-20 mA, pulse, Modbus, HART, or Profibus. These outputs should integrate seamlessly with your existing control and monitoring systems, providing real-time data for process optimization and control.

-

Installation Space Requirements

Consider the space available for installation. Some meters, like the V-Cone, require minimal straight pipe lengths, while others, like the FPI Mag, are designed for tight spaces and retrofits without service interruption. Selecting a meter that fits your space constraints reduces installation complexity and costs.

-

Fluid Compatibility

Ensure the meter is compatible with the type of fluid being measured, whether it's water, steam, crude oil, wet gas, or another substance. The material and design should withstand the operating environment, including temperature and pressure conditions.

-

Maintenance and Durability

Opt for meters with minimal maintenance requirements and robust construction to withstand harsh operating environments. Durable meters, such as those with fusion-bonded epoxy liners, offer long-term reliability and reduce downtime and maintenance costs.

Based on the knowledge developed through careful research and testing, our application engineers and designers apply their expertise in flow physics and real-world operating dynamics, resulting in some of the most accurate, innovative, and trusted flow meters on the market.

Industrial Flow Meter FAQs

How do you determine flow rate with a differential pressure flow meter?

To determine flow rate with a differential pressure flow meter, the device first measures the pressure drop across a constriction in the pipe. The flow rate is then calculated against a constant based on meter and fluid properties. Corrections for fluid density, viscosity, and temperature may be applied during this calculation. From there, the calculated flow rate is converted into a signal for integration with control systems and produces the correct output for flow rate; the flow rate is derived from the measured pressure drop, adjusted for fluid and meter characteristics.

How does a differential pressure flow meter work?

By introducing a constriction or obstruction in the pipe that creates a pressure drop, DP flow meters can precisely measure the flow of fluid within that pipe. As the pipe flow increases, more pressure drop is generated. This provides an almost-immediate response time to any pressure changes, regardless of flow velocity and other characteristics. Bernoulli’s equation asserts that pressure drop across the constriction is proportional to the square of the flow rate. Pressure sensors can measure the pressure before and after construction, so the flow rate is always accurate.

How much maintenance is needed for a differential pressure flow meter?

Because some differential pressure flow meters don’t include movable parts, they don’t require the maintenance that’s usually needed for orifice-plate or ultrasonic meter designs. Some don’t even require any recalibration, which means facility managers and other stakeholders don’t have to conduct any routine system maintenance. While alternative meter devices require additional costs for piping and structure support, some DP meters can cut both upstream and downstream pipe requirements. They offer smooth flow profiles through measurement zones to deliver accurate, reliable readings.

How will I know what line sizes are supported by the V-Cone?

Lucky for you, we have a V-Cone sizing tool that can help you to determine the right sizing measurements required for preparing and selecting a V-Cone instrument that is appropriate for what you’re looking for!

How accurate is a differential pressure flow meter?

Typically, these meters provide an accuracy of ±0.2% of the calibrated span. This means that at the lower end of a 10:1 flow range (10% of flow), which corresponds to a differential pressure range of 100:1, the flow meter could have an error of ±20% of the actual reading (AR). To ensure accuracy, stability, and installation flexibility, engineers need differential pressure (DP) flow meters that offer versatility and long-term reliability, all while minimizing maintenance and reducing operating costs.

Request Info

Looking for more information or details on our products? Feel free to fill out the form below and our team will reach out soon.

Knowledge Center

Check out further information about oil, gas, and coal applications.