- PRODUCTS

- INDUSTRIES

- RESOURCES

- SUPPORT

Flow Meters for Oil and Gas Flow Measurement

Flow Meters for Oil and Gas Flow Measurement

As the world searches for new sources of energy such as crude oil, natural gas, liquid natural gas, and coal, the demand continues to rise for reliable and accurate measurement solutions. For over thirty years, the oil and gas industry has turned to McCrometer for proven solutions in a wide range of challenging applications. With water being an essential part of the oil production and hydrofracking processes, our advanced differential pressure flow meters have consistently provided a level of performance once thought unachievable in real-world environments.

Whether your application is straight-forward or challenged by limited installation space with disturbed flow, high turndowns, wet gas, or dirty or abrasive fluids, McCrometer’s knowledgeable staff can accurately evaluate your application and specify the best meter to meet your needs.

What Our Customers Are Saying

"Extremely cost-effective product from both the initial capital expenditure and the required maintenance after installation."

Kevin Ferleyko, Ovintiv (formerly EnCana Corporation)

Featured McCrometer Flow Meters for Measuring Oil and Gas

Electromagnetic Flow Meters

Designed without moving parts, electromagnetic flow meters provide utility and support in the oil and gas industry due to their reliability and minimal maintenance requirements. This makes mag meters ideal for applications such as stimulating oil wells, hydrofracking, complex shale processes, water transfer, and produced water processes.

Our flow meters excel in remote installations where battery life and durability are crucial, ensuring seamless operation and optimal performance across various processes.

Field Mag® 3000

The Field Mag 3000 is designed for operations where rugged and quick connections are needed with the added benefit of higher temperature ratings and electrode materials in a battery powered meter.

Field Mag® 5000

Field Mag 5000 is a robust, durable meter for water transfer and mining, offering high temperature and pressure ratings, reliable Modbus data, a ProComm converter, and turnkey installation.

Advanced Differential Pressure Flow Meters

McCrometer differential pressure flow meters deliver exceptional value through low installation and ownership costs while setting the benchmark for ease of use, durability, and reliability. Engineered for rugged environments with proven results in oil & gas applications, these advanced meters offer precise and versatile flow measurement, adopted in facilities around the world as a testament to their dependable performance.

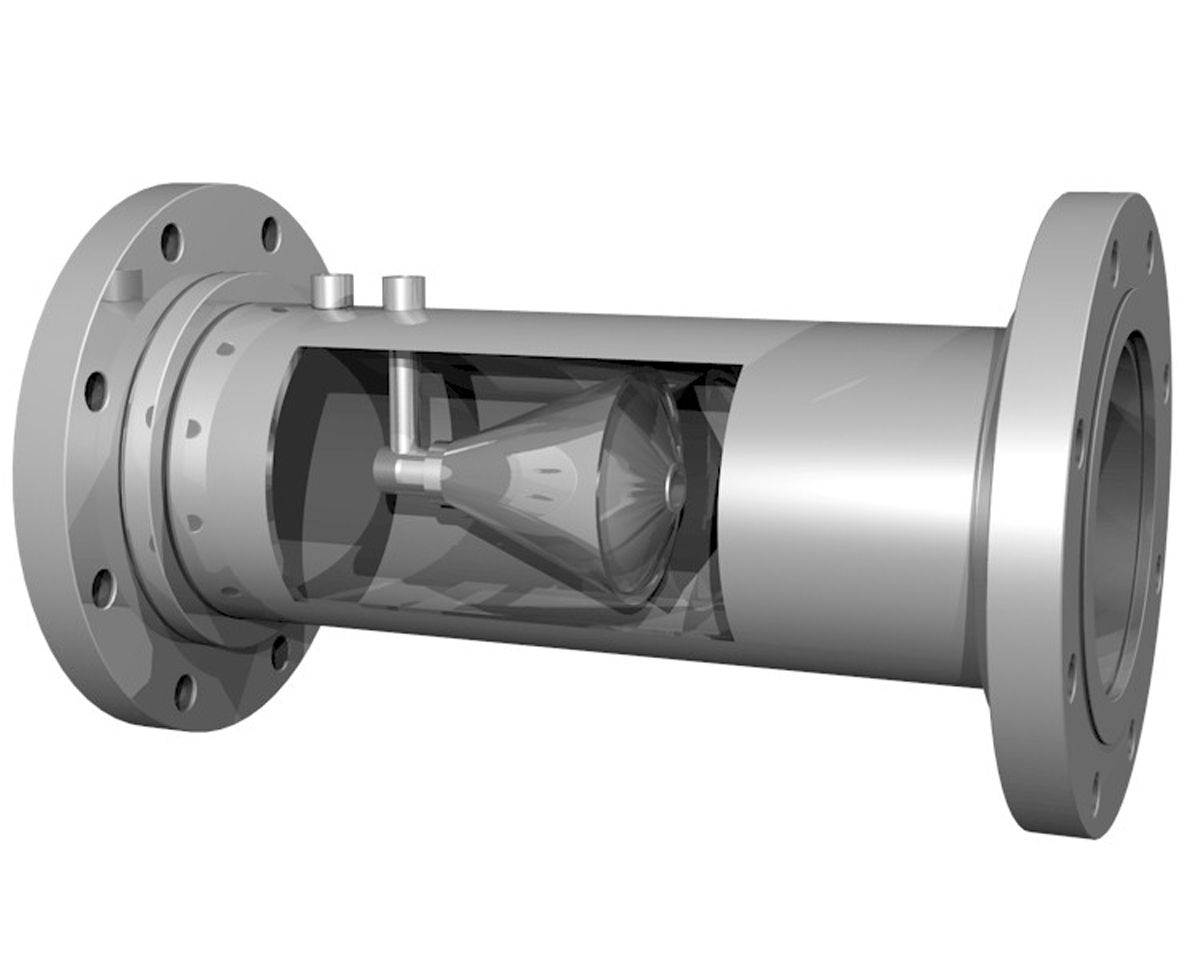

V-Cone® Meter

The V-Cone Flow Meter is a versatile, highly accurate differential pressure meter for liquid, steam, or gas, designed for challenging conditions and provides low-to-no maintenance requirement needs.

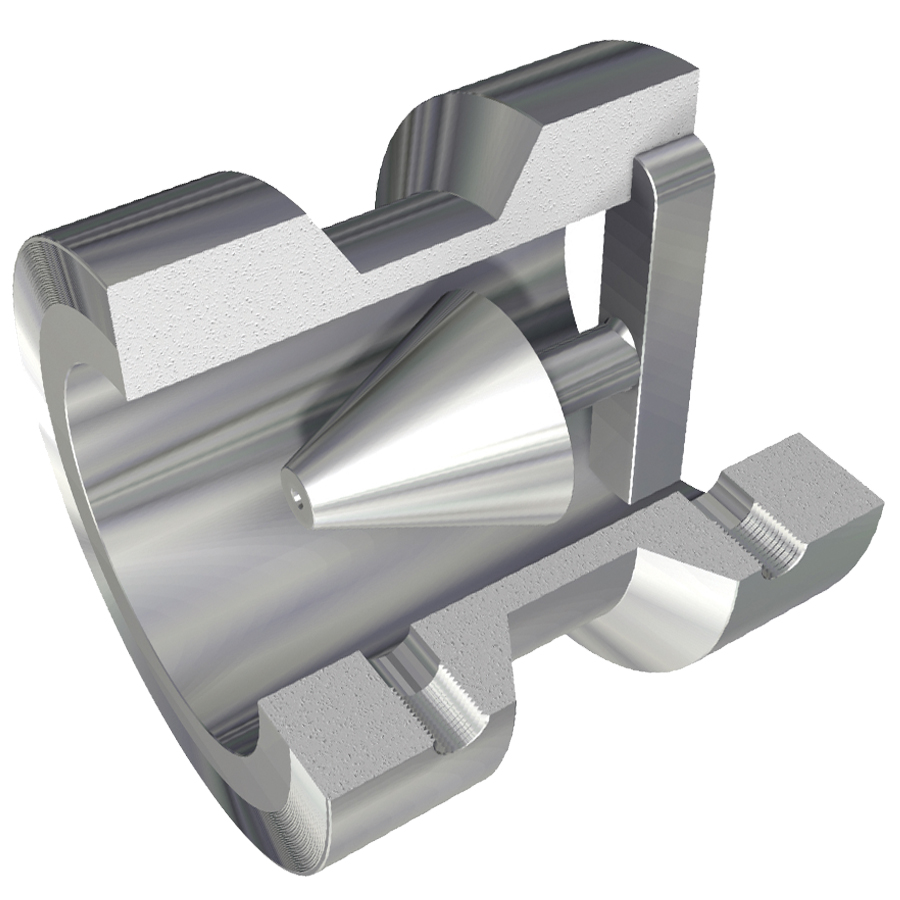

Wafer-Cone® Meter

The Wafer-Cone delivers accuracy and minimal maintenance with its compact, flangeless design, making it ideal for tight spaces and retrofits. It offers a cost-effective solution for various applications.

Propeller Meters

McCrometer’s propeller flow meters deliver outstanding value with minimal installation and maintenance costs. Known for their user-friendly design, robust construction, and dependable performance, these meters set the industry standard for accuracy and durability.

McPropeller® Meter

The Mc®Propeller is the best-selling propeller meter in the United States. Engineers have trusted it since 1955 for its life-long components, affordability, ease of installation, and operability in the industry.

Meter Electronics and Telemetry Solutions for Oil and Gas Applications

Flow Meter Electronics and Connected Hardware

McCrometer's connected telemetry solutions and electronics provide seamless, reliable remote meter reading for accurate, timely data collection, simplifying volumetric management while providing comprehensive flow measurement and data transmission. Battery-powered for remote locations, these accurate and user-configurable devices ensure minimal maintenance, with options for compatibility and versatile input/output connections.

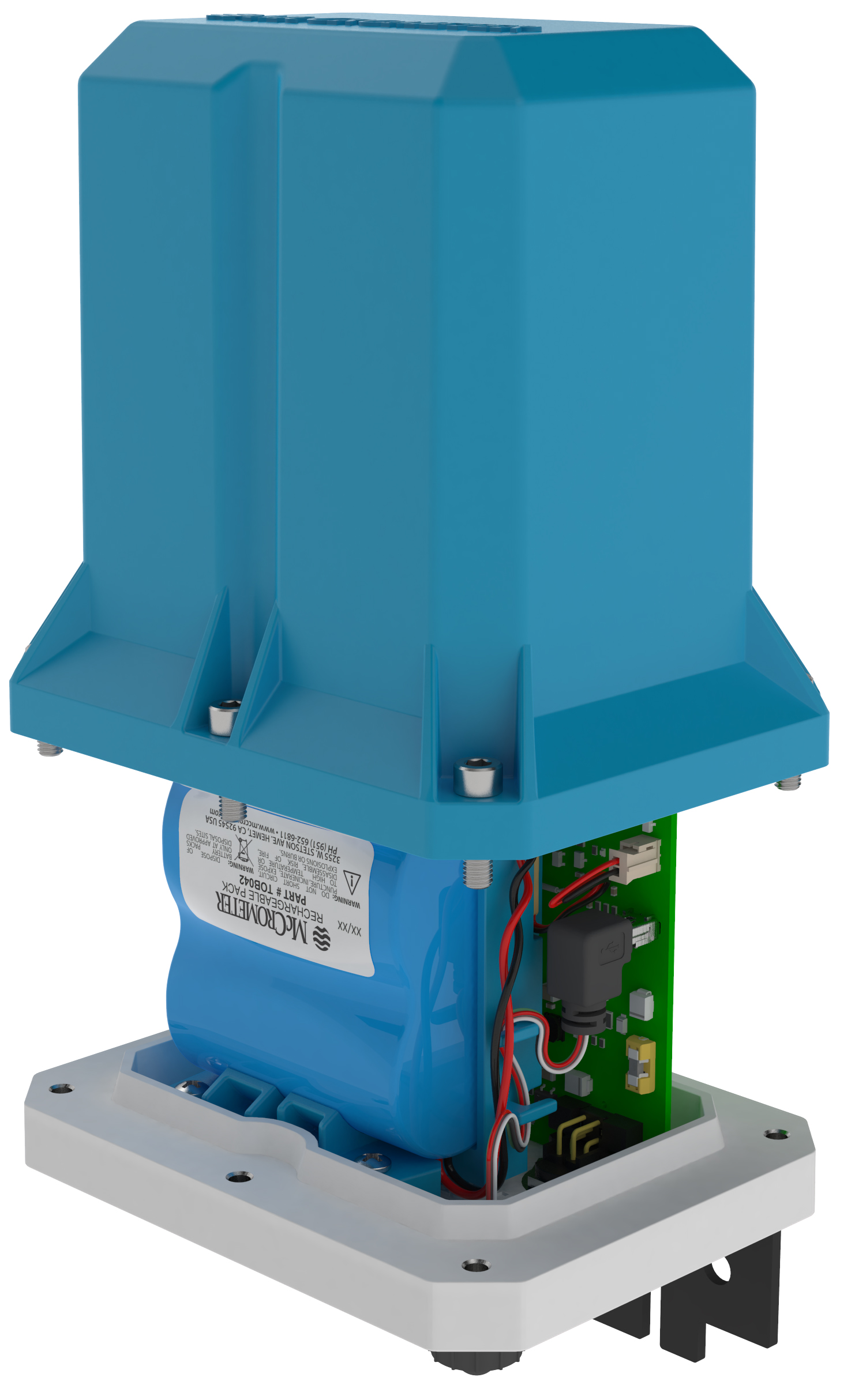

ProComm® GO

The ProComm GO is a cost-efficient, battery-powered signal transmitter, ideal for remote locations without AC/DC power. User-configurable, with accurate flow rate and velocity display, and isolated pulse outputs.

ProComm® Max

The ProComm Max signal transmitter offers advanced features such as a multi-point curve-fitting algorithm, ModBus, dual 4-20mA outputs, RS485 port, and backlit LCD with enhanced accuracy.

SmartTrax®

The battery-powered SmartTrax remote telemetry unit provides wireless telemetry of flow and sensor data. Connects to any device with pulse options and 5V analog outputs.

When it comes to flow meters, and the value they offer versus traditional differential pressure devices such as Orifice Plates, McCrometer’s V-Cone and Wafer-Cone are the better solution in many applications, often outperforming their ancestors in accuracy and flow management. They combine exceptional performance, low maintenance, and long life for superior value.

The V-Cone is ideal for use with liquid, steam or gas media in rugged conditions where accuracy, low maintenance and cost are important. McCrometer’s Wafer-Cone are highly respected by engineers restricted to small line size processes. The space-saving unit is easy to install and ideal for tight-space installations and retrofits, reducing life-cycle costs with an extended product life. Watch the V-Cone flow meter “Seeing is Believing” video to learn more!

How to Select the Right Flow Meter for Oil & Gas Applications

Whether you’re looking for greater accuracy, easy installation, control over your operations, data transfer capabilities, or improved measurement quality, there are several solutions from which to choose. When choosing a flow meter, it’s important to keep the following in mind to save on energy costs, optimize processes, and ensure accurate measurements:

-

Applications:

Electromagnetic (mag) meters have no moving parts and offer high accuracy for both clean and dirty fluid applications, making them ideal for the diverse conditions encountered in oil and gas operations.

-

Minimum and Maximum Flow Ranges:

Electromagnetic flow meters offer a broad flow range and have no moving parts to repair, providing accurate readings regardless of fluctuating flow conditions, which is crucial in the oil and gas industry.

-

Signal Transmission & Output:

Many oil and gas applications require a flow meter to issue a signal output to remote telemetry systems so operators can remotely collect flow meter data. Signal outputs are standard in telemetry-ready mag meter models, ensuring seamless integration with remote monitoring systems.

-

Installation Space Requirements:

Electromagnetic flow meters generally require less installation space compared to other types of meters. They can be installed with minimal straight-run requirements, making them suitable for tight spaces commonly found in oil and gas facilities. Whether the installation is straightforward or challenged by limited space, disturbed flow, high turndowns, wet gas, or dirty or abrasive fluids, mag meters offer flexible solutions.

-

Line Size:

Electromagnetic flow meters are available in various sizes to accommodate different pipeline diameters. They provide accurate measurements for both small and large line sizes, ensuring versatility and reliability across different applications in the oil and gas industry.

-

Maintenance and Reliability

Electromagnetic flow meters have no moving parts, reducing the need for regular maintenance and increasing reliability. This is particularly important in remote and harsh environments typical of oil and gas operations, where maintenance can be challenging and costly.

Oil and Gas Metering FAQs

Looking for the most frequent questions we get from customers regarding our oil and gas products and their applications? Our specialists and customer service team members were happy to write up any questions you may have to save you time!

Does debris affect electromagnetic flow meters?

Electromagnetic flow meters are generally resistant to debris due to their design. They can handle suspended solids or debris if the particles do not obstruct the flow sensor electrodes. Larger particles or excessive debris can potentially interfere with the measurement accuracy, necessitating periodic maintenance to ensure optimal performance in challenging environments. Read further in our blog post about deciding which differential pressure meter type is right for you.

What is the difference between the Field Mag 3000 and the Field Mag 5000?

Both meters excel in rugged Water Transfer and Mining as they’re designed with epoxy liner and grooved end fittings to fit various applications. Both products are manufactured with higher temperature coatings and pressure ratings, with access to ModBus data output and versatile ANSI flanges for blending operations. However, the difference is that the Field Mag 3000 is equipped with a battery-powered transmitter (ProComm GO) while the Field Mag 5000 comes loaded with the ProComm Max, offering modular communications protocols and outputs.

What is the difference between the V-Cone and the Wafer Cone?

The V-Cone and Wafer Cone are both differential pressure flow meters, but with distinct differences. The V-Cone is designed for high accuracy across various flow conditions, using its unique cone-shaped design for superior performance in challenging applications with a custom built, fixed-beta ratio. In contrast, the Wafer Cone offers a compact, space-saving design with easy installation, ideal for applications where simplicity and low-profile installation are key considerations with the added flexibility of a removable cone for changing conditions.!

How will I know what line sizes are supported by the V-Cone?

Lucky for you, we have a V-Cone sizing tool that can help you to determine the right sizing measurements required for preparing and selecting a V-Cone instrument that is appropriate for what you’re looking for!

Request Info

Looking for more information or details on our products? Feel free to fill out the form below and our team will reach out soon

Further Reading

Check out further information about oil, gas, and coal applications.

-

3 Things You Didn’t Know about the V-Cone

Blog Post

-

4 Reasons to Combine Telemetry with Flow Measurement

Technical Article

-

V-Cone vs. Orifice Plate: Similarities and Differences

Case Study