- PRODUCTS

- INDUSTRIES

- RESOURCES

- SUPPORT

Electromagnetic Flow Meters for Municipal

Electromagnetic Flow Meters for Municipal

Get Reliable Flow Measurement from our Mag Flow Meters

Electromagnetic flow meters, also known as mag meters or magnetic meters, are volumetric flow meters designed without moving parts, minimizing maintenance and replacement needs. Our mag meters deliver exceptional accuracy, maintaining a precision of ± 0.5% or better across a broad range of flow rates.

With over 65 years of expertise in flow measurement, McCrometer is a global leader in electromagnetic flow meters. Our commitment to innovation and top-tier quality in flow instrumentation sets us apart. We offer a diverse range of full bore and insertion-style electromagnetic meters, ideal for agriculture, municipal, industrial, and oil and gas applications. While mag meters are typically used for water-based liquids, some models can also measure mixed media such as slurries and sludge.

How Municipalities Can Utilize Electromagnetic Meters

If you’re managing effluent or influent water systems, accurate and repeatable flow measurement is crucial for optimizing data collection and enhancing flow control. Whether you’re dealing with water storage, transmission lines, or treatment processes, flow meters and quality control are likely the biggest influences to your water system.

Electromagnetic meters, propeller meters, and differential pressure flow meters deliver exceptional value with low installation and maintenance costs... but what is known about their ease of use, rugged durability, and reliability? These advanced meters set the industry standard for various sectors, but can they be trusted in facilities worldwide? Learn how mag meters can help you achieve precise flow measurement and improve your municipal operations.

Our Mag Meters are Known for:

Durability: Our electromagnetic meters are backed by a range of warranties, having been rigorously tested to meet the industry's highest standards.

Innovation: McCrometer has been developing solutions for our customers and improving flow meters since 1955.

Quality: McCrometer is a global specialist. We design, manufacture, install, and test all of our own flow meters.

How do Electromagnetic Flow Meters Work?

Mag meters function based on Faraday’s Law of Electromagnetic Induction to measure liquid velocity. According to this principle, a conductor moving through a magnetic field generates an electric signal within the conductor, which is directly proportional to the fluid's velocity. As the fluid flows through the magnetic field, conductive particles within it cause changes in voltage. These variations are then used to measure and calculate the water flow velocity through the pipe.

Mag Meter Product Suite

Our goal is to be our customers’ advisor and partner from project inception to ongoing metering champion.

Electromagnetic Flow Meters

Insertion mag meters can be installed with an easy hot-tap process that does not disrupt flow or production.

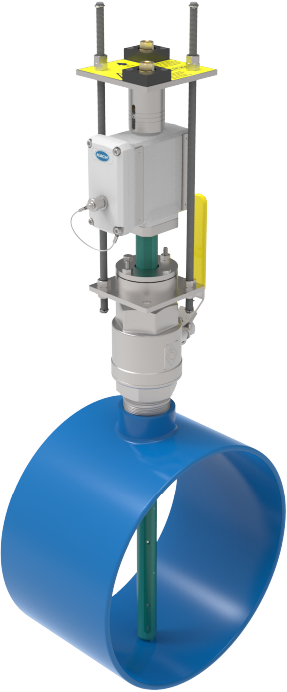

FPI Mag® 3000

The FPI Mag, equipped with the ProComm GO, is the full-profile insertion mag meter ideal for new and retrofit projects. The FPI Mag’s hot-tap installation eliminates the need to interrupt service, de-watering lines, or cutting pipe, ideal for retrofits and tough applications.

FPI Mag® 5000

Paired with the ProComm Max, the FPI Mag 5000 is a full-profile insertion mag meter perfect for both new and retrofit projects. It's hot-tap installation enables seamless integration without service interruptions, de-watering lines, or pipe cutting, making it ideal for retrofits and challenging applications.

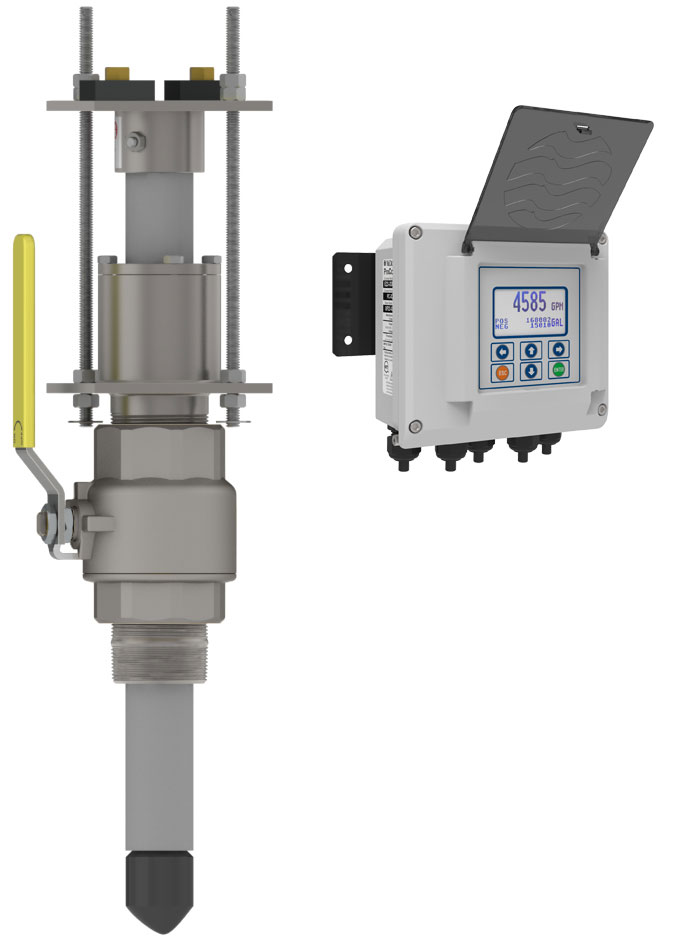

SPI Mag® 3000

The single-point insertion SPI Mag is the cost-effective, accurate mag meter ideal for slurries, sludge, potable water, pulp stock, and more. Unlike conventional magnetic meters, the SPI Mag's cost is independent of pipe size.

SPI Mag® 5000

The SPI Mag, a single-point insertion electromagnetic meter, offers a cost-effective solution for measuring slurries, sludge, potable water, pulp stock, and more. Paired with the ProComm Max, the SPI Mag stands out from conventional magnetic meters as its cost remains independent of pipe size.

Closed Bore Electromagnetic Flow Meters

Designed for the specific needs of the water treatment, water distribution, collection, and waste treatment segments in Municipal. Custom configurations can be quoted to meet installation specifications.

Ultra Mag® 3000

The Ultra Mag 3000 features the ProComm GO, an NSF-approved fusion-bonded epoxy UltraLiner™ and a lifetime liner guarantee, eliminating the risk of delamination and liner separation, and is ideal for applications near pumps, water wells, and other municipal locations.

Ultra Mag® 5000

The Ultra Mag 5000 is a cutting-edge electromagnetic flow meter designed for precision and durability. Equipped with the ProComm Max, this flow meter offers advanced communication and control capabilities, ensuring accurate flow measurement and seamless integration with various monitoring systems.

Mag Meter FAQs

Our specialists and customer service team members are happy to answer any questions you may have. In the meantime, here are a few we answer a lot.

What industries are best suited for electromagnetic flow meters?

Magnetic flow meters are highly effective for a wide range of water-based applications, and they offer exceptional value in the municipal industry. They are particularly well-suited for managing water distribution and wastewater treatment systems. The absence of moving parts in mag meters ensures reliable performance with minimal maintenance, making them an ideal choice for municipal settings where consistent operation and low upkeep are crucial.

What is the accuracy of McCrometer mag meters?

Each product has a unique accuracy level, such as our Ultra Mag and FPI Mag products offering up to ±0.5%. Our SPI Mag series offers up to ±2%.

Does debris affect electromagnetic flow meters?

Electromagnetic flow meters are generally resistant to debris due to their design. They can handle suspended solids or debris if the particles do not obstruct the flow sensor electrodes. Larger particles or excessive debris can potentially interfere with the measurement accuracy, necessitating periodic maintenance to ensure optimal performance in challenging environments. Read further in our blog post about deciding which differential pressure meter type is right for you.

What is the difference between the FPI Mag and the SPI Mag?

The FPI Mag, a full-profile insertion meter, can extend its range in a closed pipe application with a +/- 0.5% accuracy rating and can be easily installed via hot-tap setup on any lay length required. The SPI Mag, a shortened-profile meter, is equipped with a shorter flow sensor rated for a +/- 2.0% accuracy at a fraction of the cost of an FPI Mag; however, each application is dependent on the line size of your application and the application space required for installation.

What else do I need to know about electromagnetic flow meters?

It’s clear why many engineers favor mag meters for municipal applications, but they aren’t ideal for every scenario. Electromagnetic meters perform best with fluids that have a conductivity of 20 ohm/cm or higher. Therefore, they may not be the most suitable choice for low-velocity applications or fluids with lower conductivity, such as petroleum-based substances.

Request Info

Looking for more information or details on our products? Feel free to fill out the form below and our team will reach out soon

Knowledge Center

Check out further information about oil, gas, and coal applications.

-

Electromagnetic Meters and Ultrasonic Meters – A Comparison

Technical Article

-

Know the Flow: Measurement Where You Need it the Most

FPI Mag white paper

-

The FPI Mag and ProComm GO: A Versatile New Opportunity for Water and Wastewater Applications

Blog Article