- PRODUCTS

- INDUSTRIES

- RESOURCES

- SUPPORT

Flow Meters for Municipal Applications

Flow Meters for Municipal Applications

Municipal water facilities require highly durable and precise flow measurement instruments for efficient operation. McCrometer flow meters excel in providing accurate and cost-effective solutions for applications such as water treatment plants, distribution systems, and pumping stations.

Our meters offer exceptional value in installation and ownership, addressing the unique challenges of confined spaces and varied flow conditions. By listening to customer needs and innovating unique solutions, we ensure reliable performance in managing the essential water resources of our communities.

What Our Customers Are Saying

“We deal with many different types of meters and applications where the meter display needs to be calibrated, which takes extra time... I’m pleased that we could install the FPI Mag so quickly, and the display right away made it easy to see it was working!”

Ryan Goodrich, Ashley Valley Water & Sewer Improvement District

Featured McCrometer Municipal Flow Meters

Electromagnetic Flow Meters

Designed without moving parts, electromagnetic flow meters are highly favored in the municipal market due to their reliability and minimal maintenance requirements, making them ideal for applications such as water treatment and distribution.

They excel in remote installations where battery life and accuracy are crucial, ensuring seamless operation and optimal performance across various municipal processes; their compact design fits tight spaces, and their operation is unaffected by debris, making them robust and dependable.

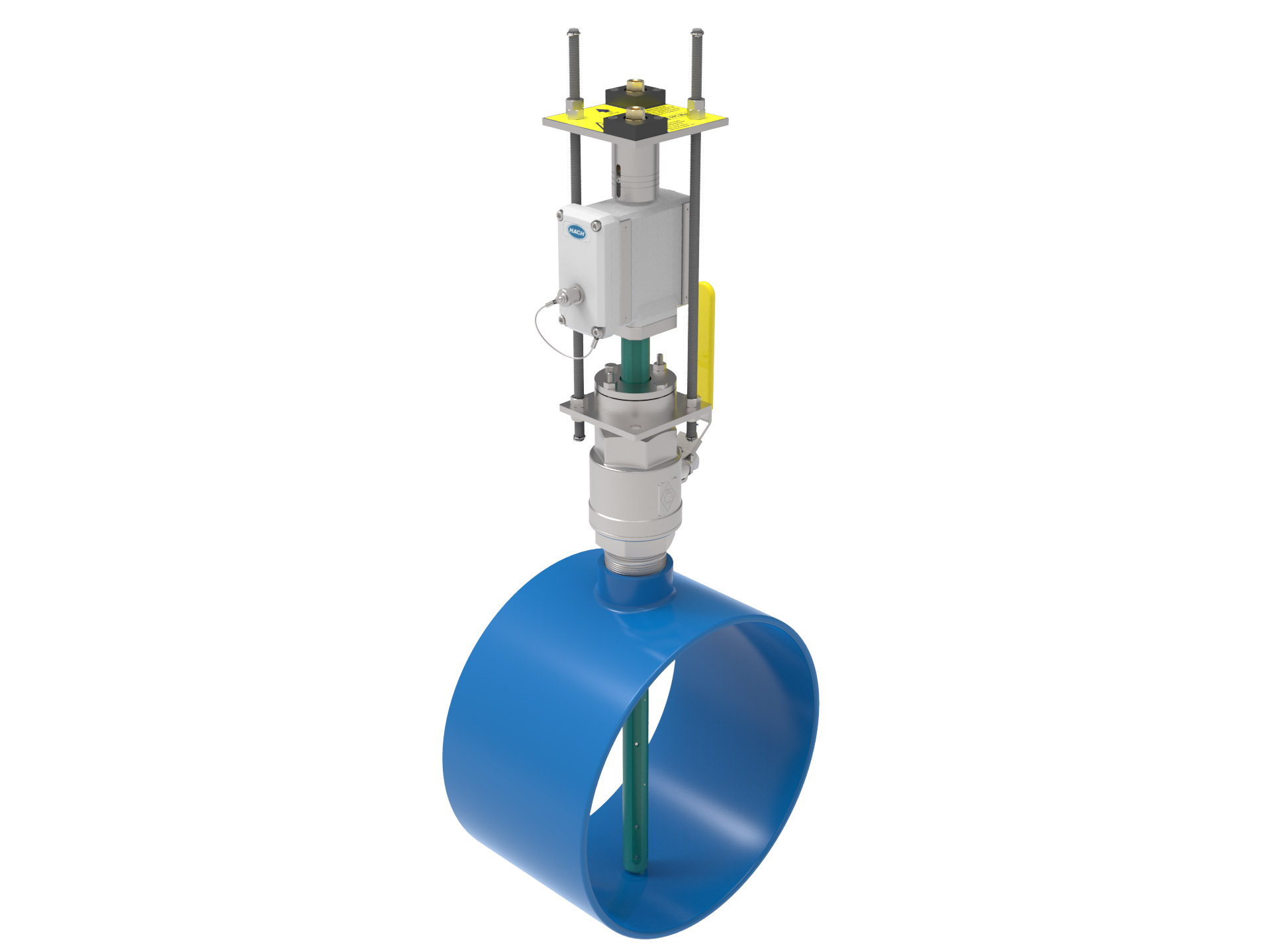

Ultra Mag® 3000

Inline magnetic flow meter with advanced features, resistant to abrasion and corrosion, and equipped with the ProComm GO, offering data communication and integration capabilities.

Ultra Mag® 5000

Equipped with ProComm Max, the Ultra Mag 5000 offers superior data collection and ensures highly accurate flow measurement, making it ideal for precise and efficient municipal water management.

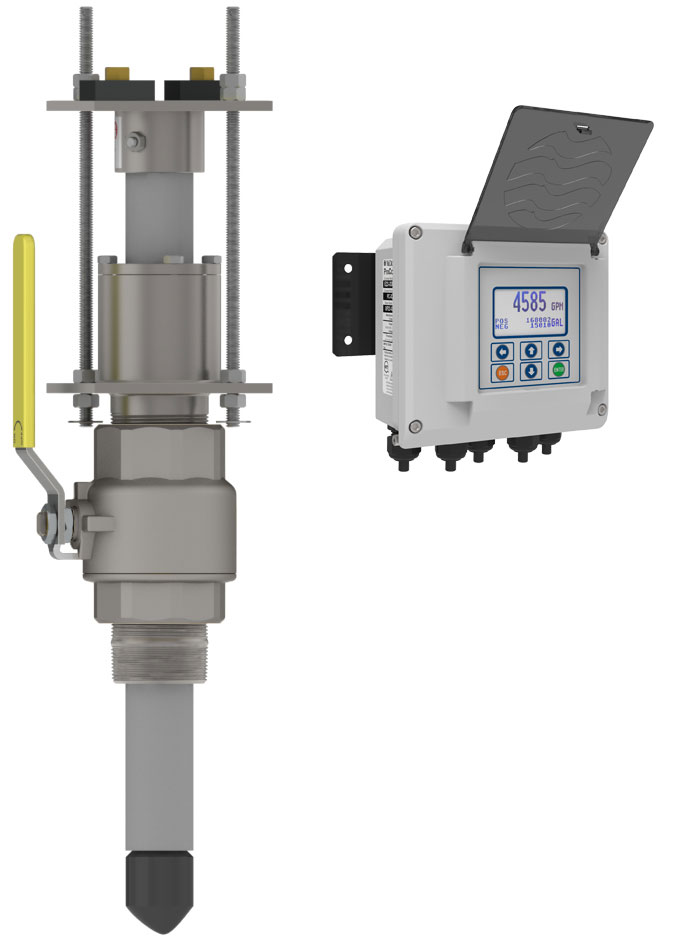

FPI Mag® 3000

The FPI Mag 3000, equipped with ProComm GO, ensures precise flow measurement in tight spaces with easy hot-tap installation, ideal for retrofit projects and municipal use.

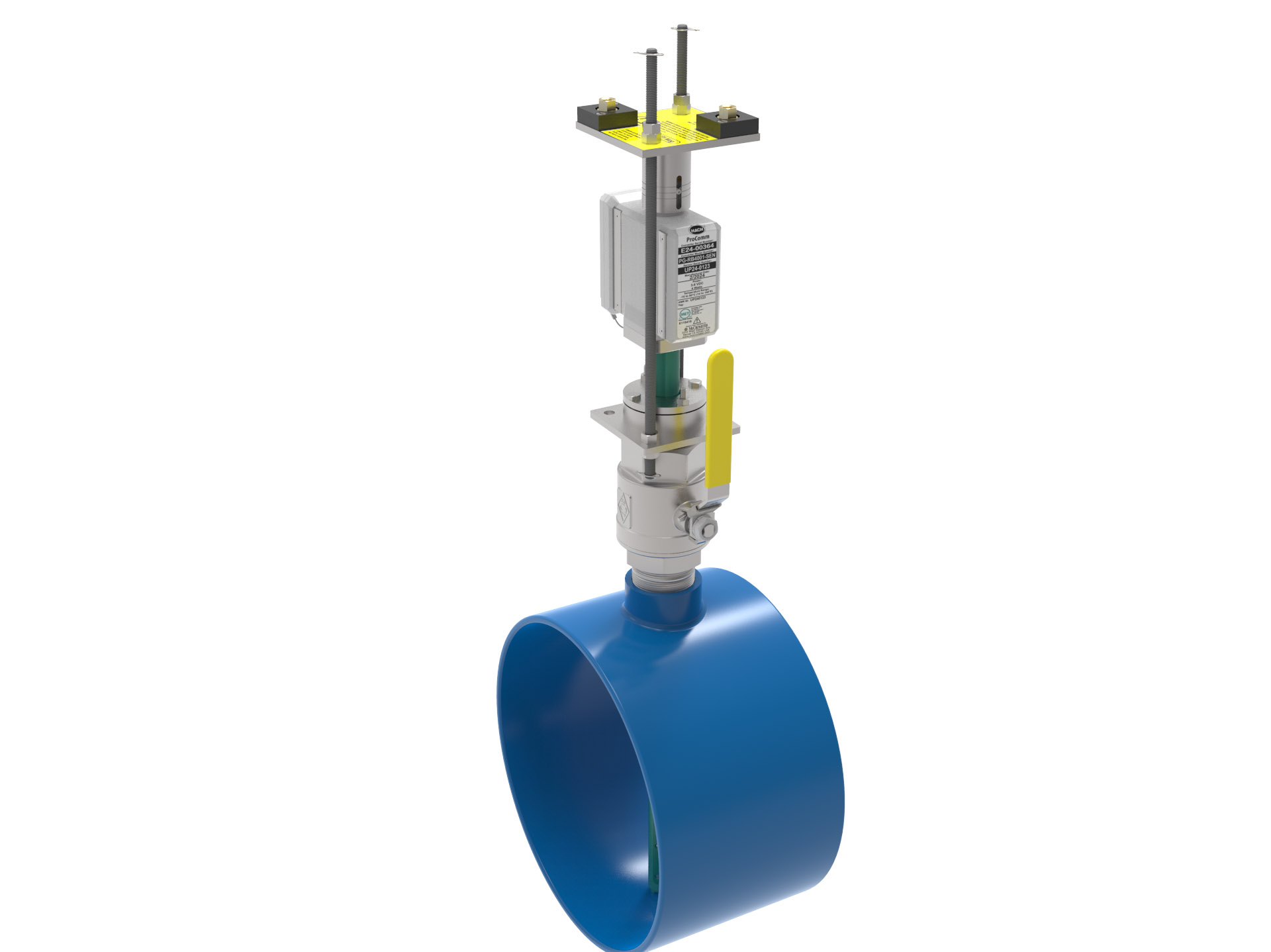

FPI Mag® 5000

FPI Mag 5000 with ProComm Max ensures precise flow measurement with advanced integration options like HART and Modbus. Features reliable output signals and easy hot-tap installation for seamless retrofit.

SPI Mag® 3000

The SPI Mag 3000 Meter provides a highly cost-effective solution for the accurate measurement of liquid flow in closed conduit, pressurized pipe applications with the ProComm GO as a major highlight.

SPI Mag® 5000

Paired with the ProComm for enhanced data communication and integration, the SPI Mag 5000 uses velocity and pipe diameter information to measure flow accurately across a wide range.

Propeller Meters

McCrometer’s propeller flow meters deliver outstanding value with minimal installation and maintenance costs. Known for their user-friendly design, robust construction, and dependable performance, these meters set the industry standard for accuracy and durability.

Water Specialities® Flow Meter

Available with mechanical or digital registers, the Water Specialties flow meter offers ±2% accuracy, versatile output options, and supports custom lay lengths designed for standard temperatures up to 140°F.

McPropeller® Meter

The Mc®Propeller is the best-selling propeller meter in the United States. Engineers have trusted it since 1955 for its life-long components, affordability, ease of installation, and operability in the industry.

Advanced Differential Flow Meters for Municipal

McCrometer differential pressure flow meters deliver exceptional value through low installation and ownership costs while setting the benchmark for ease of use, durability, and reliability. Engineered for rugged environments, these advanced meters provide precise and versatile flow measurement. Widely adopted in facilities around the world, they ensure accurate data and dependable performance in diverse industrial and municipal applications.

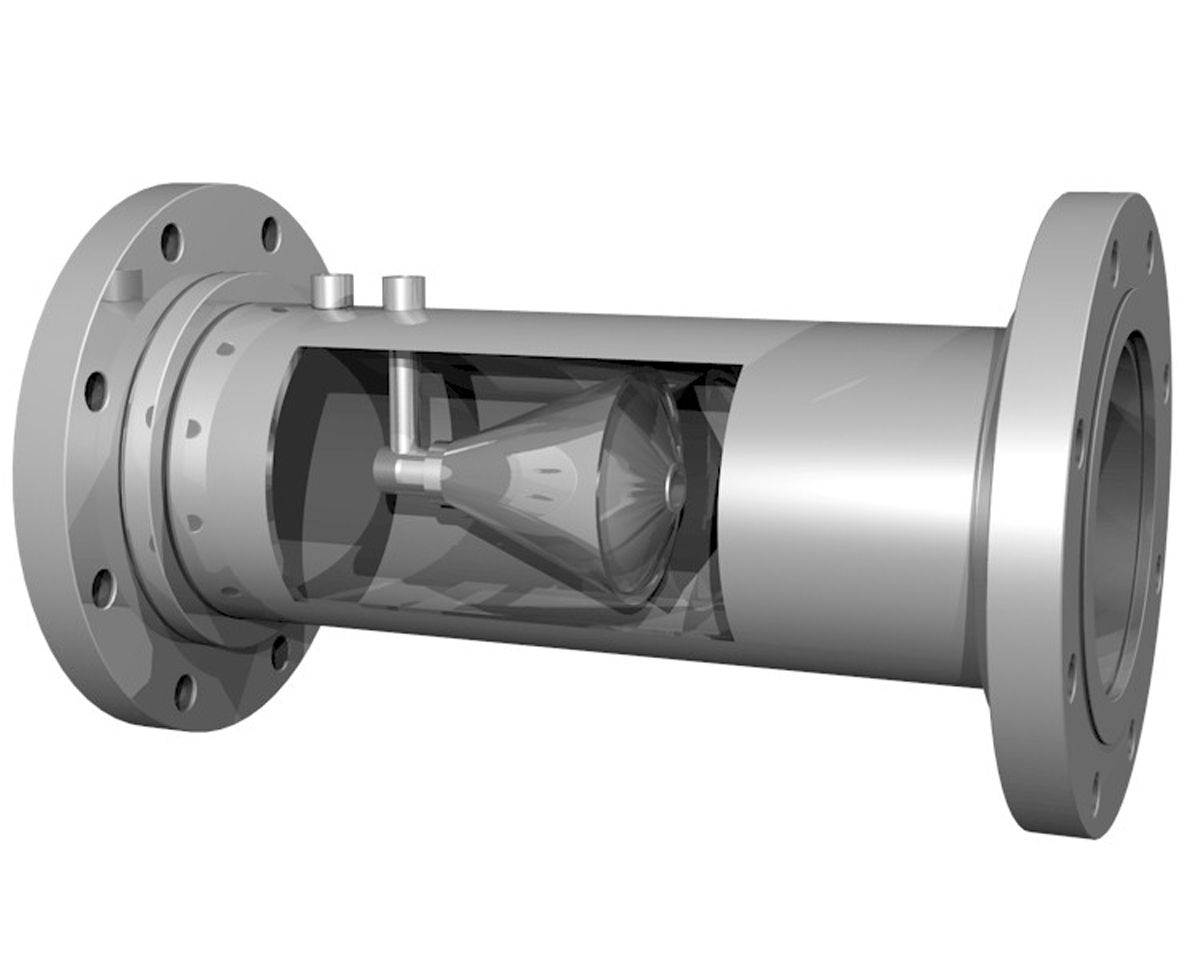

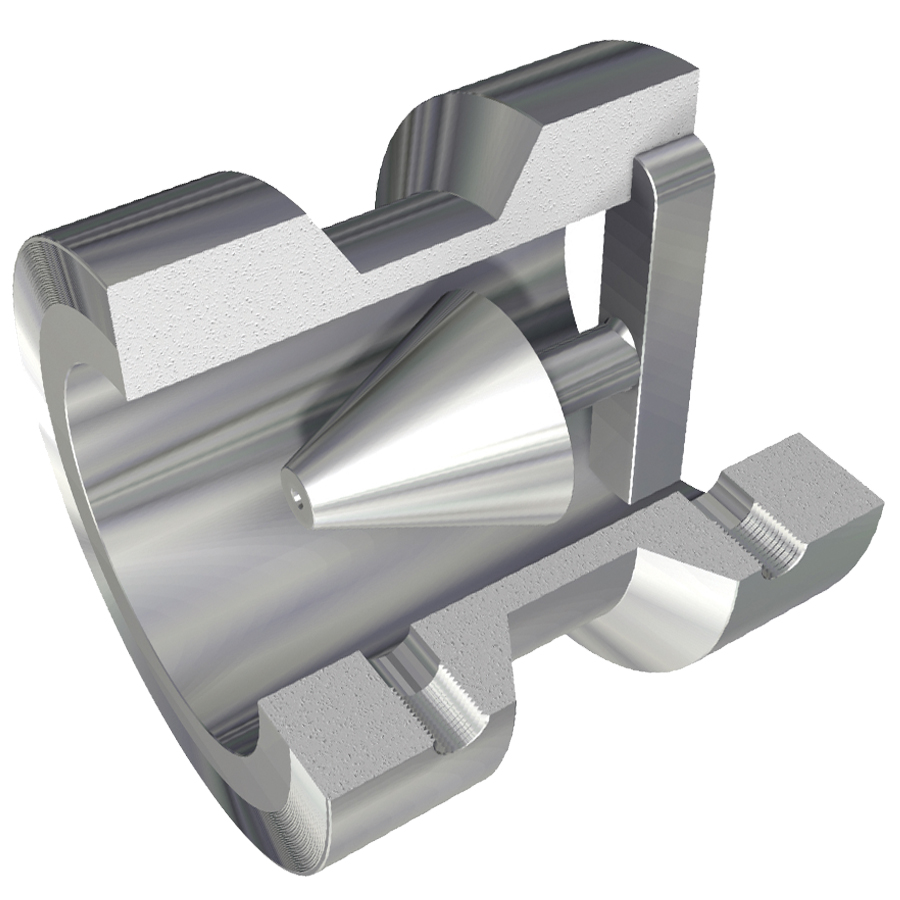

V-Cone® Meter

Known for its superior accuracy and repeatability in both mild and harsh environments, the V-Cone® Flow Meter is an advanced differential pressure instrument designed for challenging conditions.

Wafer-Cone® Meter

The Wafer-Cone delivers accuracy and minimal maintenance with its compact, flangeless design, making it ideal for tight spaces and retrofits. It offers a cost-effective solution for various applications.

Meter Electronics and Telemetry Solutions for Municipal Applications

Flow Meter Electronics and Connected Hardware

McCrometer's connected telemetry solutions and electronics provide seamless,reliable remote meter reading for accurate,timely data collection, simplifying volumetric management while providing comprehensive flow measurement and data transmission. Battery-powered for remote locations, these accurate and user-configurable devices ensure minimal maintenance, with options for compatibilty and versatile input/output connections.

ProComm™ GO

The ProComm GO is a cost-efficient, battery-powered signal transmitter, ideal for remote locations without AC/DC power. User-configurable, with accurate flow rate and velocity display, and isolated pulse outputs.

ProComm™ Max

The ProComm Max signal transmitter offers advanced features and enhanced accuracy with a multi-point curve-fitting algorithm, dual 4-20mA outputs, RS485 port, and backlit LCD.

FlowCom®

The battery-powered FlowCom remote telemetry unit provides wireless telemetry of flow and sensor data. Connects to AMI-compliant devices with pulse options and 5V analog outputs.

Open Channel Flow Solutions for Municipal Applications

Hach’s Flow Solutions by McCrometer

Acquired by McCrometer, the Hach Flow product line delivers open channel solutions to municipalities with integrated systems that ensure accurate flow measurement. Known for quality and operational reliability, Hach water management products are designed for open channel applications; visit our FAQs page to learn more about Hach Flow capabilities.

FLO-DAR® Sensor

The FLO-DAR sensor provides users with highly accurate non-contact flow measurement from above. Build with precision in mind, the sensor ensures flow data to be uninterrupted or disturbed.

FH950 Flow Logger

Designed for portable use in the field, the battery-powered and lightweight FH950 flow logger excels in measuring turbulent, noisy, or shallow flows in various municipal applications.

FL900 Flow Logger

Reliable and cost-effective, the FL900 flow logger is specifically designed to reinforce engineer safety and enhance efficiency in challenging open channel applications for municipals.

FL1500 Flow Logger

The FL1500 stationary flow logger offers agile, accurate, and integrated flow measurement through multi-sensor data collection operations, making it ideal for various water quality monitoring needs.

Data Delivery Service (DDS)

Our monthly subscription solution enables any field service team to accurately manage data collection for flow measurement. Services available using industry-level flow monitoring products and operation.

FSDATA™ Online Application

Unlock flow measurement data with FSDATA, a comprehensive digital software solution that allows you to remotely access, monitor, program, and report on all of your field instruments from wherever.

If you’re managing effluent or influent water systems, accurate and repeatable flow measurement is crucial for optimizing data collection and enhancing flow control. Whether you’re dealing with water storage, transmission lines, or treatment processes, flow meters and quality control are likely the biggest influences to your water system.

Electromagnetic meters, propeller meters, and differential pressure flow meters deliver exceptional value with low installation and maintenance costs... but what is known about their ease of use, rugged durability, and reliability? These advanced meters set the industry standard for various sectors, but can they be trusted in facilities worldwide? Learn how mag meters can help you achieve precise flow measurement and improve your municipal operations.

Selecting The Right Flow Meter for Municipal Applications

Each year, thousands of instrument engineers, from municipal drinking water facilities to industrial process plants with wastewater treatment operations, find themselves stuck in understanding how flow measuring devices provide unmatched accuracy in even the most challenging applications.

Not every flow meter that you come across can do the job of another; each unique flow meter on the market has a unique use case, so being mindful of your application comes into play when making a decision on what type of meter solution you’re interested in. For example, some organizations may look to retrofit a large portion of their water line but don’t want to dewater pipelines, so a full-profile insertion meter might be best suited for this challenge. However, if installation isn’t an issue but low total cost of ownership and data accuracy are more important, than a inline magnetic flow meter might be of better use.

When deciding what type of municipal flow meter you’re interested in, you’ll want to consider a few factors that will impact your decision making process and the outcome of your project:

-

Application of Municipal Flow Meters:

When deciding on the type of municipal flow meter for your project, consider the specific application and the type of media being measured. For example, electromagnetic flow meters are ideal for water and wastewater applications due to their accuracy and reliability with conductive fluids. Other things to consider include flow range, installation space, maintenance needs, budget, and compatibility of the flow meter with your media, ensuring it can handle the required pressure and temperature ranges required. Lastly, confirm your installation requirements; some McCrometer products can be installed without flanges, cutting line, shutting down or welding pipes, depending on your line specs.

-

Signal Outputs Needed:

Municipal flow meters typically offer various signal output options to align with existing control and monitoring systems. Common outputs include 4-20 mA, pulse, Modbus, HART, and Profibus, providing necessary data for process control and optimization. To measure the success of your project, monitor the flow meter’s performance over time; key performance indicators include accuracy, reliability, and maintenance frequency. Successful implementation is marked by consistent, precise data that helps optimize your processes, reduce costs, and improve efficiency. Conversely, frequent calibration issues, maintenance needs, or data inconsistencies could indicate that the selected flow meter might not be the best fit for the application.

-

Media Compatibility:

Media compatibility is vital for flow meters as it ensures accurate and reliable measurements, extends the meter's lifespan, and minimizes maintenance needs. Municipal flow meters must handle potable water, chemicals used in treatment processes, raw wastewater, effluent water, sludge, and other fluids in municipal applications. Proper compatibility helps meet regulatory standards, optimizes operational efficiency, and reduces costs by preventing damage and ensuring smooth system performance.

Based on the knowledge developed through careful research and testing, our application engineers and designers apply their expertise in flow physics and real-world operating dynamics, resulting in some of the most accurate, innovative, and trusted flow meters on the market.

Municipal Flow Meter FAQs

How do electromagnetic flow meters work?

Mag meters operate under the principle of Faraday’s Law of Electromagnetic Induction to measure liquid velocity. The principle of operation states that a conductor moving through a magnetic field produces an electric signal within the conductor, which is directly proportional to the velocity of the water moving through the field. As fluid flows through the magnetic field, conductive particles in the fluid create changes in voltage across the magnetic field. This variation is used to measure and calculate the velocity of water flow through the pipe.

How do you determine flow rate with a differential pressure flow meter?

To determine flow rate with a differential pressure flow meter, the device first measures the pressure drop across a constriction in the pipe. The flow rate is then calculated against a constant based on meter and fluid properties. Corrections for fluid density, viscosity, and temperature may be applied during this calculation. From there, the calculated flow rate is converted into a signal for integration with control systems and produces the correct output for flow rate; the flow rate is derived from the measured pressure drop, adjusted for fluid and meter characteristics.

How much maintenance is needed for these kinds of meters?

Because electromagnetic flow meters don’t include movable parts, they don’t require the maintenance that’s usually needed for orifice-plate or ultrasonic meter designs. Mag meters also do not rely on transducer cleanliness, like ultrasonic meters. Although maintenance can be occasional, some meters don’t require any recalibration, making them easier to control for facility managers. While alternative meter devices require additional costs for piping and structure support, differential pressure meters, such as the V-Cone, can cut both upstream and downstream pipe requirements. They offer smooth flow profiles through measurement zones to deliver accurate, reliable readings.

How accurate are McCrometer flow meters?

Typically, differential pressure meters provide an accuracy of ±0.2% of the calibrated span. Our Ultra Mag and our FPI Mag offer up to ±0.5% of the calibrated span, while our our SPI Mag and Water Specialties propeller meters offer up to ±2%.

Request Info

Looking for more information or details on our products? Feel free to fill out the form below and our team will reach out soon.

Further Reading

Check out further information about municipal applications.

-

Electromagnetic Flow Meters: A Complete Guide

Blog Post

-

5 Keys to Selecting a Mag Meter

Technical Article

-

FPI Mag Meter Solves a Tight Installation Challenge at Lake Huron

Case Study