- PRODUCTS

- INDUSTRIES

- RESOURCES

- SUPPORT

Case Study

Article | March 1, 2023

Download as a PDF document

Kelly Arnold, distribution supervisor, and Jay Hollen, city engineer for the city of Buckhannon, recently ran into a situation that didn’t add up. A flow meter at one of the city’s booster stations was indicating a flow rate higher than the capacity of the station’s pumps.

“Installing the McCrometer FPI Mag® flow meter confirmed what we already knew: The old meter was showing a flow rate of 450 gallons per minute or more, but we were actually pulling only 350 gallons per minute. The old meter was showing a flow rate much higher than the capacity of the pumps at the booster station,” said Arnold.

The flow meter causing the problem was an older full bore mag meter. Whenever re-calibration of the meter was necessary, the line had to be shut down, a whole section of pipe needed to be removed and a new meter had to be installed.

Arnold continued, “Having to pull out the old meter would have involved an $8,000 investment to remove it, send it in and required buying a new in-line meter to make sure operations could continue. Going with the FPI Mag flow meter was a much bigger savings in terms of downtime and costs.”

The charming city of Buckhannon, West Virginia, lies along the scenic Buckhannon River, northeast from the state capital city of Charleston. The city’s water department serves a population of about 22,500 residents in the greater area, providing the “best drinking water” in North Central West Virginia according to the West Virginia Rural Water Association. The city’s water treatment plant utilizes water from the Buckhannon River, which is also an important outdoor recreational asset and tourist draw to the area.

At the city’s Tennerton booster station, the staff routinely monitors how much water is pumped through the station to a nearby public service district (PSD) and another area where there is a different pressure zone. That data is used to determine if there are any leak problems by subtracting the PSD meter’s flow rate from the Tennerton station’s flow rate.

Arnold said, “The FPI Mag meter serves as a totalizer at the booster station to monitor the flow through the pumps to ensure the system is operating efficiently. If we see excessive usage, then that indicates a problem and we have to address it.”

Hollen added that it was important to resolve the inaccurate flow reading issue because not only is the city receiving inaccurate flow data, but it is also considering upgrading the pumps at the booster station based upon increased demand. Hollen said, “We need to have the most accurate flow reading information available to ensure that the correct pumps (as far as output is concerned) are selected.”

The department’s staff regularly compares how many gallons per minute their pumps are drawing, which is what led them to suspect the accuracy problem with the old full-bore meter. The data helps them spot leaks and other issues before they cause major problems. Arnold noted a few years ago that an underground leak near the area’s high school went undetected for 18 to 20 hours, resulting in a lot of wasted water and high operational expenses.

The Buckhannon city staff contacted the applications team at McCrometer about its flow meter accuracy problem. The McCrometer team recommended the FPI Mag flow meter, which is designed to deliver consistent, highly accurate results within the challenging flow profiles of the booster station. Featuring a unique hot tap design for easy installation and removal, with low maintenance requirements, the FPI Mag provided an ideal fit to the city’s need.

The installation process at the booster station was simple, with the insertion of the FPI Mag meter taking less than one hour. If the city had pulled the old meter out and replaced it, Arnold explained the booster station could have been down for as long as 4 to 6 hours.

Arnold said, “I see more advantages to using the FPI Mag meter. You can quickly hot tap into the pipe for installation and so there’s less downtime. It’s also easier to retrieve for maintenance. If there’s a need to shut it down, we can get it back in service right away. This meter is doing a really good job. Over time, it it’s going to save us money.”

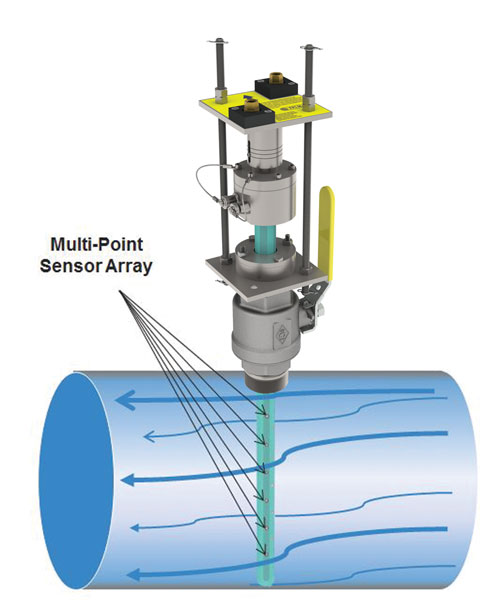

With the city staff’s commitment to high quality drinking water, the FPI Mag flow meter’s next generation design solved an important operational problem at the booster station. The meter’s advanced sensor features multiple coils and electrodes assembled in a tube that inserts completely into the pipe to measure the full profile of the flow stream, providing exceptional accuracy even in challenging flow conditions.

The meter’s signal converter features an advanced filtering algorithm to support accuracy of ±0.5% from 1 to 32 ft/s and ±1% from 0.3 to 1 ft/s. The signal converter also includes: built-in dual 4-20 mA outputs for communication flexibility, additional programmable outputs to support SCADA systems and a simplified menu structure for ease of use. These features make it easy for any city staff member to connect the meter to the facility’s monitoring system.

With no moving parts, there is nothing to wear or break on the rugged FPI Mag flow meter. No recalibration in the field is necessary. The sensor body is made from heavy-duty, 316 stainless steel for maximum structural integrity. The sensor body is hermetically sealed and protected by an NSF-certified 3M-fusion-bonded epoxy coating.

Arnold says it all adds up correctly now in terms of flow rates at the Tennerton booster station with the new FPI Mag flow meter. The Buckhannon city water department staff is pleased with the meter’s accurate performance and simple installation. “The way the FPI Mag meter measures reliably combined with its hot tap insertion design makes it a whole lot more dependable and easier to maintain.”

The FPI Mag, according to Arnold, will definitely be considered the next time the city purchases a new meter. “We replaced another meter not long ago and if we had known about the FPI Mag meter at that time then I’m sure we would have looked really hard at that as an option,” said Arnold.

Hollen continued, “There have even been discussions with our water treatment plant about the installation of an FPI Mag meter on our high-service pumps’ discharge lines to more accurately determine the amount of potable water being distributed throughout the system.”

© Copyright McCrometer, Inc. | 3255 West Stetson Avenue, Hemet, CA 92545 USA | +1-800-220-2279 | Fax +1-951-652-3078 | HR secure fax (866) 753-7459

To view the Partnership Homepage, select "Your Account" in the top right corner, and choose "Partnership Home"